Cantilever Racks

Holding long, bulky, and irregularly shaped items like lumber, metal bars, pipes and tubing, equipment, or furniture, Meco and Red Steel cantilever racks can help organize the largest and most difficult goods kept in your warehouse. As cantilever racking is great for storing heavy-duty items, the correct installation is essential for ensuring safety. If done improperly, rack failure and employee injuries can occur. With 60+ years of expertise, we’re here to handle the hard work. Let us assist you with determining the specific storage solution that’s best for your business and installing your cantilever racking securely.

Click here to find out more about our installation services.

|

|

|

What is a Cantilever Rack?

A Cantilever Rack is comprised of three components:

An ideal system for storing furniture, steel bars, pipes & tubing, or any other long, heavy items too large for other

industrial storage solutions, cantilever racks are a series of arms, uprights, and bracers that provide instant accessibility to both full cargo loads and individual pieces. The open design allows forklifts to easily take loads off and put loads back on, and the modular nature of the racks allows for easy expansion if storage requirements change.

These components must be ordered in the appropriate quantities and capacities.

Cantilever Uprights

Uprights consist of a vertical column and a horizontal base which is bolted to a column. A minimum of two uprights must be ordered to form a storage bay. Each edge of the column is punched vertically on 3" centers so it may be used as a single or double sided upright depending on the size of the base used.

Holes are provided in the base to anchor the upright to the floor. Uprights must never be attached to walls, columns or other structures.

Cantilever Arms

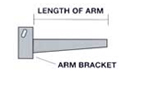

Cantilever arms are the heart of the rack system. Proper selection can make or break a successful storage plan. Shelving offers straight arms (generally used for storing stable loads such as lumber, steel sheets, cartons and skids) and inclined arms (for cylindrical objects or loads that tend to roll forward). Arms can be adjusted on 3" centers up and down the upright and are available in lengths to 60" in a variety of capacities. Standard arm color is gray.

Straight Arm Straight ArmStraight arms up to 48" long have a minimum pitch of 3/8" per foot to compensate for deflection. 54" and 60" arms have a minimum pitch of 5/8" per foot.

Inclined Arm Inclined Arm

Inclined arms have a pitch of 20 degrees or approximately 4.36" per foot.

Hair Pin Keeper Hair Pin Keeper

The hair pin keeper permits instant adjustability and is easily inserted and removed for adjustment of arm height. Lips are available on all arms.

Brace Sets

"2B" Horizontal Brace Pattern

Used on 6' to 10' Medium duty uprights and 8' Heavy duty and Series 2000 uprights.

"3B" Horizontal Brace Pattern

Used on 12' Medium duty uprights and Series 2000 uprights and 12' x 14' X Series upright.

"4BX" Horizontal Brace Pattern

Used on 15' to 20' Heavy duty and X Series uprights and all structural cantilever rack.

"4BXX" Horizontal Brace Pattern

Used on all 15' to 20' uprights when the brace length exceeds 84" centerline to centerline of upright.

Designing a Cantilever Rack System

The key to a successful cantilever rack system is the answer to one question: What is the product (load) being stored? The answer must include the length, depth, height and weight of the product. Once this data is ascertained it becomes a simple matter to determine the required arms, uprights and braces.

1. Determine the number and spacing of arms.

The load must be supported by enough arms to prevent load deflection. Deflection may cause damage to the load being stored as well as the arms (figure A1). To detect deflection, place the load over two wooden blocks (to represent cantilever arms) as shown in figure A2. If deflection is not present it is acceptable to use a two are system as long as this does not create an overload condition. If the load shows deflection use three blocks as shown in figure A3 or four blocks as in figure A4.

IMPORTANT: The load should overhang the end arms by one-half the distance from upright centerline to upright centerline. Failure to observe this measure may cause an overload condition on the arms.

2. Determine the length of the arms.

The depth of the load should never exceed the length of the arm. A 48" wide bundle of plywood requires a 48" long arm, bundles of steel 24" wide require a 24" arm and so on. Rated arm capacities may be seriously diminished if proper loading techniques are not observed. Figures B1, B2 and B3 illustrate correct and incorrect arm loading.

3.Determine the height of the upright.

When determining the height of the upright it is important to consider the ceiling height, forklift reach, sprinkler systems and other factors, such as local building codes, that might effect the overall height.

|

|

|